In the current age of IoT

Hon

Chuan Group has been

committed to providing beverage packaging materials to beverage manufacturers.

In light of recent food safety issues in Taiwan, Hon Chuan Group prioritizes the establishment of a

transparent production traceability system that envelops elements from raw

material production to production facilities in order to reestablish consumer

confidence and allow administrative regulation and inspection.

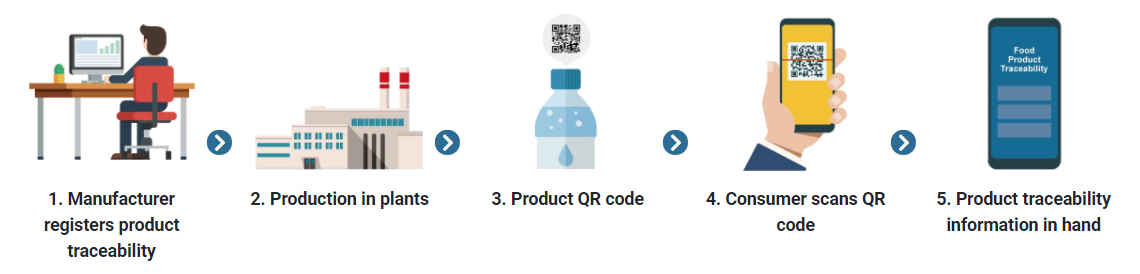

Food Product Traceability

The introduction and application of QR code contribute to the management of food safety information. By integrating the QR code system into food safety management, consumers are able to gain access, through mobile devices, to the food traceability system provided by beverage manufacturers online to retrieve beverage production information not available to them before now. Major beverage manufacturers can register on this system information such as source of raw materials, inspection records, production sites, and production time. In doing so, brand quality can be strengthened, giving consumers confidence and assurance in purchasing and consuming products.

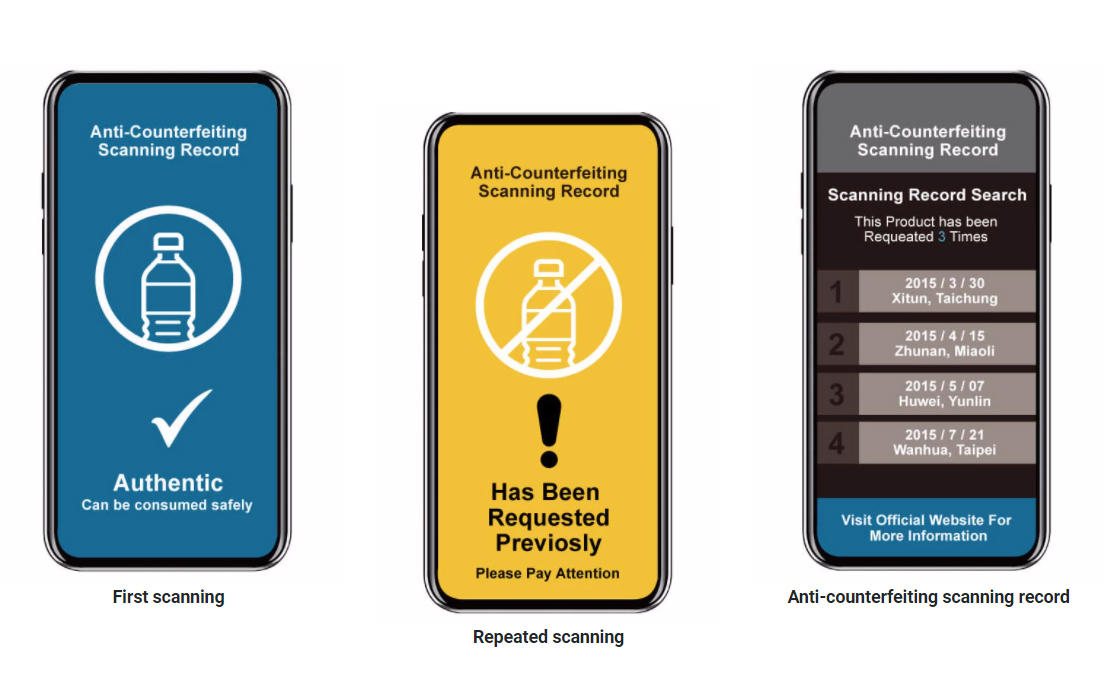

Anti-counterfeiting

Using IoT’s

anti-counterfeiting function to verify product authenticity.

Anti-channel conflict

The system

records the location where the product is scanned and delivers anti-channel

conflict warning to the manufacturers in the event of occurrence. When items

shipped to Location A are scanned excessively at Location B, the system sends a

channel conflict warning to safeguard the operating mechanism of the

manufacturer and the distributer.

Production Control

The virtual and physical integration of software and hardware in future production plants allow real-time collection, filtering, retrieval, and storage of production data. Also, the existing ERP can also be integrated in for subsequent sales management such as orders and inventories management. By collecting and analyzing production data from remote production facilities as well as generating accurate forecasts, we are able to increase added-value of equipment, expand the application services market, and realize highly efficient, real-time service.

Product Management

Product management using the IoT system assigns an exclusive QR code to each product, realizing “one product one code” management. This is similar to personal identification and enables effective product management. Personal identification is an important aspect of citizen administration. Similarly, beverage identification exclusive to every bottle is the best management strategy to guarantee food safety

Integration with E-commerce and Third-party Payment

Virtual

distribution channels of different industries are flourishing, such as JD and

Taobao. Integration of product QR code with online E-commerce platform allows

consumers to scan physical items and place orders online. Third-party payment

can also be incorporated to secure trade between both parties.

Promotions

Promotions and

rewards are frequent in the competitive beverage market. By using Hon Chuan Group’s IoT system and QR code’s implicit

information design, marketing personnel can freely present a variety of new

promotional strategies such as reward points, membership system, and

third-party payment rewards to enrich consumer experience and boost product

sales. After the consumer has scanned the product, he or she may select

Promotional Draw to enter the draw and enter telephone number to receive prize

notification.

Advertisement and Publicity

In the past,

beverage manufacturers have primarily used television, print advertisement, and

internet as means of advertisement and publicity. In the future, consumers can

view advertising collateral with a scan of the bottle cap. They can also

experience more entertainment value for the product in games, entertainments

and music.

Surveys

A surveys can

be conducted on the IoT platform, allowing consumers to directly interact with

manufacturers and eliminate distrust between the two parties to rebuild

confidence.

Big Data Analysis

Future system

can perform data analysis on information scanned into the system by consumers

to enable precision marketing. Basic information acquired in production

management can be organized and analyzed for market trends as well as demographic

information such as age and profession. Processed information can also be used

to trigger alerts for deviation, production expiration, and overstock analysis

to drastically improve production efficiency.